The chosen bottle.

I made a part for the body, a part for the clear plastic cap, and an assembly for the screw-on pump lid.

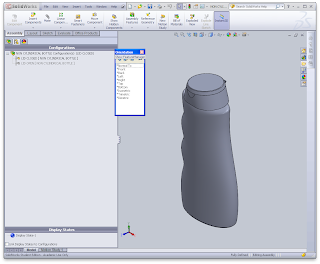

The body was quite simple to make, requiring just a revolve, a screw thread and an extruded cut through the top.

Isometric of the body.

I then created an assembly for the pump lid. I decided to make and edit parts inside this assembly instead of creating each one separately and importing them at the end.

I modelled the parts I could see by simply unscrewing the lid but this was not enough. I had to break the chamber open to gain access to the valve parts.

Some of the parts that make up the screw lid.

The chamber on the right was broken open for access.

I modelled the components within the assembly, paying attention to connections, sizing and interference between parts.

Isometric view of the lid assembly.

Section of the lid assembly.

I then created a part for the clear plastic cap within this assembly to ensure a proper fit but saved it externally.

Separate part for the cap.

I created another assembly and imported the two parts and the lid assembly. These three components were fully mated together.

Exploded view of the bottle assembly.

This assignment was easier than I expected, I was able to get this far in the space of one afternoon and night. It seems difficult, but really it is just a series of revolves around one centre line. Creating parts inside the assembly made it much easier.